TEE probes are exposed to significant wear as part of everyday normal use.

Significant savings add-up with a TEE probe preventive maintenance program. Last month, we provided an overview of TEE probes and in prior posts provided evidence that suggests that adding ultrasound probes to a comprehensive PM program can contribute to long-term cost savings and greater returns on investments. Based on the design and use of TEE probes, they are an excellent candidate for preventive maintenance. Yet few facilities consider TEE probes capital assets and almost none have added them to a PM program. The following might be considered a case study that examines just that, the benefits of specifically developing a TEE probe preventive maintenance program or AEM (Alternative Equipment Maintenance) Plan.

Currently, manufacturers of ultrasound probes and systems do not recommend preventive maintenance on TEE probes and only offer costly replacements ($20,000 – $40,000 each). After repairing over 185,000 ultrasound probes, with over 40,000 being TEE probes, we’ve acquired a full understanding on points of wear, modes of failure, and model-specific characteristics. Combine this with our material selection process, testing, and qualification processes, the teams at Innovatus can confidently speak to this topic.

Punctures and perforations to the bending rubber, and subsequent fluid invasion during disinfection, is the primary cause of TEE probe failures…and is the primary reason that many TEE probes are beyond repair. The bending rubber starts to become more-brittle after 100-150 uses. This is due to the acidic nature of GI fluid and the harsh chemicals used in disinfection. As the bending rubber becomes more-brittle, it is more apt to perforate when encountering a sharp object such as a tooth, surgical instrument, or other hard surface or object.

Knowing that bending rubber damage WILL occur at some point, is this component not a prime candidate for preventive maintenance?

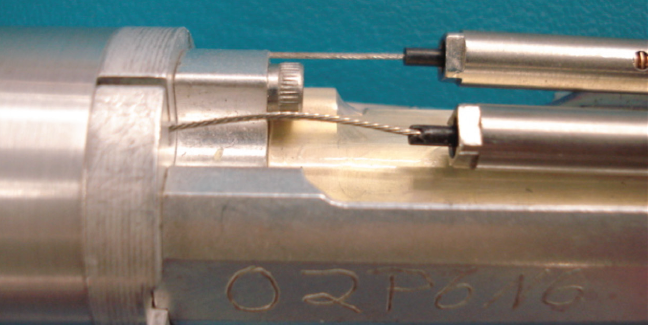

Another common failure is articulation, or tip deflection. Over time, the internal steel cables that control articulation will stretch and fray, similar to old shoelaces. Eventually the distal tip’s range of motion becomes reduced, leading the users to exert greater force on the knobs, adding more stress to an already compromised cable. Eventually, the articulation cables break from continued stress.

Knowing that the articulation components are a point of wear, is this area not another candidate for preventive maintenance?

Just like many standard probes have sealant surrounding the acoustic lens, so do certain TEE probes, specifically 3D volumetric TEE probes, such as the Philips X8-2t, GE 6VT-D, and Siemens Z6M. Over time, the sealant, medical-grade caulking as an example, will degrade and wear-away. Eventually, the lack of sealant will leave a void, potentially allowing gross fluid invasion during disinfection. Again, gross fluid invasion is the primary reason that TEE probes fail and that many are beyond repair.

Just like many standard probes have sealant surrounding the acoustic lens, so do certain TEE probes, specifically 3D volumetric TEE probes, such as the Philips X8-2t, GE 6VT-D, and Siemens Z6M. Over time, the sealant, medical-grade caulking as an example, will degrade and wear-away. Eventually, the lack of sealant will leave a void, potentially allowing gross fluid invasion during disinfection. Again, gross fluid invasion is the primary reason that TEE probes fail and that many are beyond repair.

Is this not yet another argument for adding TEE probes to a preventive maintenance program?

Interestingly, the three items above can be visualized and monitored over time, but in reality, it seldom occurs. Departments that perform TEE studies are legally required to log each probe’s use, by serial number or other identifier. Depending upon usage, 100-150 uses may span less than 90 days at some facilities, 1-year at others. Operator’s Manuals cite the importance of end-users, and those performing probe disinfection, to be performing visual inspections. It’s also recommended that echo-techs perform a functional check of the articulation between each use inspecting range of motion. A good practice is to address the items above at a minimum of every 6-9 months.

Our data indicates that TEE probes have an annual failure rate of 65% – 100%.

This translates to a catastrophic failure on each TEE probe every 12 – 18 months. In some facilities, this rate is 100% – 150% or one every 6 – 12 months. Obviously, this is dependent upon the practices in-place and the level of care and handling occurring at each facility. Our data is not expected to indicate the failure rate at your facility. An example of an annual PM to a 3D TEE probe would consist of:

- Replacing the bending rubber

- Adjusting the articulation’s range of motion, and

- Replacing the seal surrounding the acoustic lens

Let’s do a cost analysis

For the sake of conversation, let’s place the cost of an annual PM at $1000, the cost of an OEM replacement 3D TEE at $22,000, and the average cost of repairing a 3D TEE at $5,000. What also needs to be considered is the loss of revenue due to canceled patient studies due to TEE probe failures. Let’s also assume that your facility supports 10-TEE probes. Below is a model that suggests that adding TEE probes to a PM program offers considerable savings over the traditional OEM model. Even if additional TEE probe failures occur, the cost savings are significant.

So where do you begin?

It’s easy as 1, 2, 3

Start by inventorying your TEE probes and adding them to a PM schedule. As PM’s are required, request a no-charge loaner to maintain your customer’s uptime. Innovatus will send the loaner, you use the existing box and shipping label provided to return your probe, and we’ll return it in a matter of a few days. Complement this with partnering with echo-techs and central processing staff to perform visual inspections, leakage testing, and proper care and handling and you’re set for success.

Innovatus Imaging publishes a TEE visual inspection guide that can be used educationally and even posted to keep the concept of visual inspections top-of-mind. The guide can be downloaded from the resources section of our website and printed, or we can send high quality hard copies to your facility. Our team is also available to hold training sessions and assist with assessing the quality of TEE care and handling at your facility. Learn more about our SafeTEE program here. We welcome setting up a TEE PM program designed to meet your particular facility’s needs. We’re also able to show you the potential savings based on YOUR data. Click the link to send an email to our SafeTEE team.