When it comes to imaging devices, little things go a long way…and not always in the right direction. A little slip of the hands could cause significant trauma to your TEE probes. According to years of data from first-hand experience and researching common failures, trauma is one of the leading reasons for costly TEE probe repairs or replacements. Did you know? Catastrophic damage that leads to costly TEE probe replacements is 100% fully preventable! Innovatus Imaging can help you reduce TEE probe failures.

How and Why TEE Probes Fail

Many clinicians believe that “biting” is one of the primary causes of TEE probe damage.

Yet, research conducted by our Centers of Excellence shows that physical damage occurs during transportation, set-up, and insertion.

Additionally, the process of disinfecting a transducer with physical damage, such as a hole in the bending rubber or crack in the distal tip, is one of the primary causes of irreparable catastrophic damage.

Research also shows that many of the little things that lead to big repairs are easily avoidable, if not 100% fully preventable.

Consider the following typical costs

| Option | Minimum | Maximum |

|---|---|---|

| OEM Exchange | $12,000 | $50,000 (pediatric TEE) |

| 3rd-Party Exchange | $5,000 | $40,000 (pediatric TEE) |

| Repair Cost | < $500 | About $10,000 |

A SafeTEE process analysis can help change all of that

What is a SafeTEE Process Analysis?

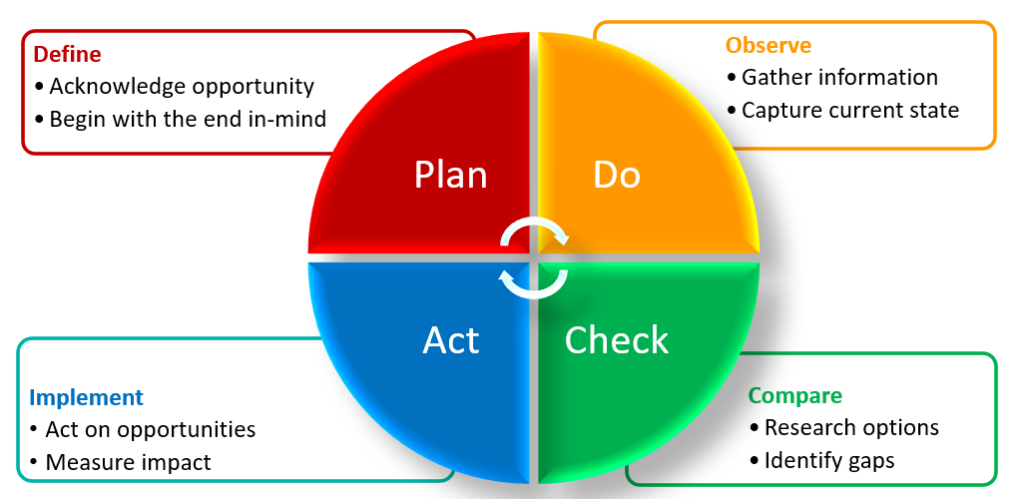

The program follows a Continuous Quality Improvement Model…and it has been proven highly effective.

The process involves 1) Acknowledging the problem and assembling the right team, 2) Identifying the current state, 3) Comparing current-state to industry best-practices, and 4) implementing key process improvements. Repeat as needed. High-cost TEE probe replacements can be a thing of the past.

By implementing the SafeTEE Process Analysis Program, facilities of all sizes can drastically reduce their support costs, capital expenses, and overall cost of ownership for TEE probes. Our pilot customer supported 10-TEE probes, yet experienced 28 catastrophic failures stemming from trauma and gross fluid invasion, totaling over $250,000 in a single year.” By modifying key steps in cross-functional processes, this customer achieved the following results in less than 6-months:

- 2022: 6-month window

- 50% failure rate reduction

- 75% reduction in failure severity (need to replace)

- 68% cost reduction

- Current data

- Preventable failures: 0

- Cost of preventable failures: $0

- Results

- Increased customer satisfaction and increased access for patients and physicians

How Does the Program Work?

- You’ll assemble your team of stakeholders (typically leaders/managers from any department that handles TEE probes). This typically includes Cardiology, Central Processing, Anesthesia, and Clinical Engineering (acting as point). We’ll arrange a quick kick-off meeting to explain the program via Teams or other conferencing software to your stakeholders. We’ll discuss the purpose, the goals, everyone’s responsibilities, and the expected outcomes.

- In a second meeting (once the stakeholders have committed), we’ll train one or more of the Clinical Engineering team to be the TEE probe experts in your facility. We’ll provide them with the knowledge and our proprietary tools to capture current state.

- Your TEE probe expert will capture current state in about 1-hour’s time via an off-line worksheet or on-line web-form. Once complete, the data will be sent to our clinical and technical experts. We’ll determine strengths, opportunities, and the resources needed to achieve ideal outcomes.

- We’ll schedule a follow-up debrief with you and your stakeholders. We’ll review a comprehensive report showing current state complete with photos, highlighting best-practices, and providing opportunities for improvement. Together, we’ll define what processes should be modified and the managers able to implement change. With some very minor updates to the processes in each area, costly catastrophic failures can be eliminated.

- Finally, we’ll schedule very brief training sessions with those responsible for the cleaning and disinfection process. We’ll discuss why, when, and how to perform quick, but thorough, visual inspections. The team will utilize our TEE probe visual inspection guide as a reference to potentially identify compromised components PRIOR TO high-level disinfection.

After over 10-years of success, we’ve proven that following these tips can eliminate the need to repair or replace TEE probes due to preventable damage. You’ll migrate from a model based on reaction to one based on prevention.

The Process Analysis Program is just one of the segments in our comprehensive SafeTEE program. Our experts provide your teams with the tools and training needed to become the TEE experts in your facility!

To learn more about the SafeTEE Program, go to innovatusimaging.com/safetee or contact us at: safetee@innovatusimaging.com