A checklist of standards to expect and demand for sustainable MRI Coil Repair

Following are some questions to ask and things to consider about MRI coil repair processes and options to help assure you make wise, informed decisions you, your team, and your patients can live with.

1 Cable harnesses: Are raw cables replaced in a coil or are they spliced? Replacing costs more, however the longevity of the repair and extension of the life of the coil more than compensate for the extra money, enabling hospitals to lower their overall cost of ownership. Spliced cables can fail more often as they can separate over time which means more frequent repairs, more down time, and potentially more compromises with performance. Innovatus replaces all raw cable harnesses in lieu of splicing which results in having one of the highest first-time fix rates in the industry.

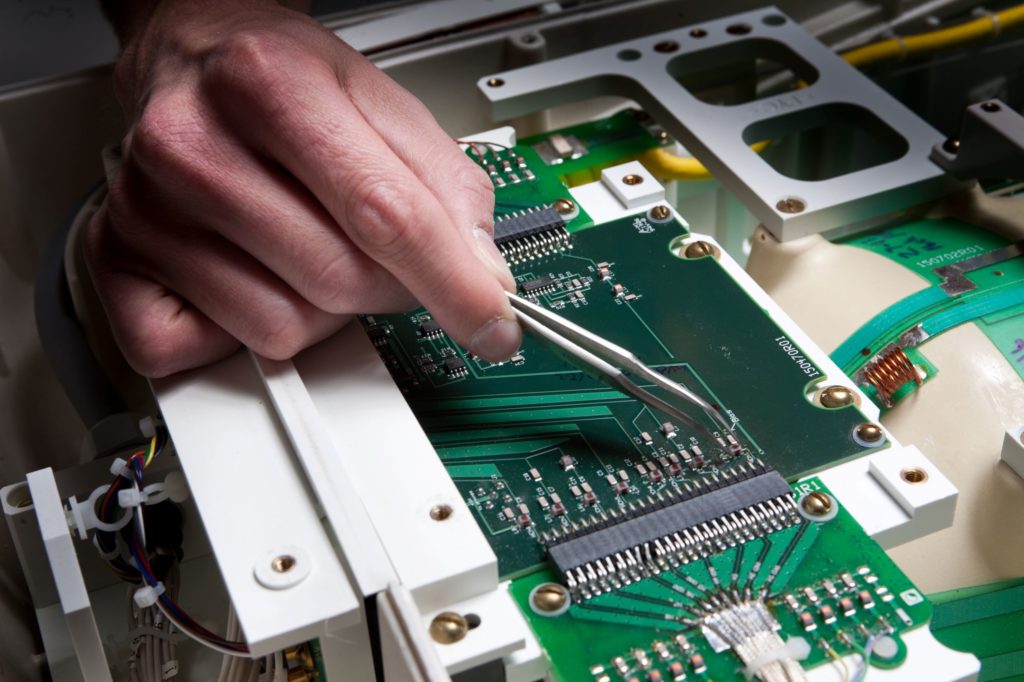

2 Testing methods: What kinds of methods are used? And are these methods capable of picking up potential hidden electrical issues? Simplistic testing often fails to pick up additional issues affecting the coils performance. Innovatus uses modular testing methods which break down the system and tests each section to the component level assuring the whole system is functioning optimally.

3 Source of mechanical parts: Are the mechanical parts used in your repair sourced from soft molding and machining or 3D printing? While 3D printing can increase speed and accessibility, this method of production does not always hold up over time as effectively as molding and machining. Its critical to know how these parts are sourced for your repairs as they can affect the longevity of the repair, and ultimately the cost of ownership and downtime associated with short-term vs. long-term repairs.

4 Inspection processes: Does the supplier tear apart the cable or use a less or non-invasive process to inspect the quality and condition of each coil? Procedures at the Innovatus MRI Center of Excellence include the use of an x-ray device to view cabling structures and avoid unnecessary disassembly which can increase the risk of other failures and extend the time for triage and repair.

5 Foundation of repair processes: What is the experience, research and processes behind the repair? This is perhaps the most critical differentiator in suppliers. Are the technicians backed by decades of experience or basic training backgrounds, and what type of proven testing processes, protocols and simulators are used for quality assurance for the repair and entire unit vs just the element under review or repair? With more than 20 years of manufacturing processes which include research for best-in-class methodology and testing, Innovatus applies some of the most proven processes available today.

More details about these issues and other considerations for optimizing MRI repair outcomes for your inventory can be found in a report about Centers of Excellence for Imaging Device repairs available HERE.

https://www.innovatusimaging.com/mri-coil-repair-2/