⛓️💥The, Hidden, Weak Link in Ultrasound Probes

When we think about ultrasound probe failures, the acoustic array often takes center stage. But right behind it—often overlooked—is the wiring harness and cable jacket. These components are critical to performance and reliability, yet they’re subjected to constant stress: continued flexing, accidental pulling, pinching, and even being rolled over. It’s no surprise they break down. Wiring failures are something with which most of us are familiar, they’re not just limited to ultrasound probes. This latest post, “Harness the Power” continues from earlier posts:

🛜 One Possible Solution

You might think wireless probes are the answer—and yes, they exist—but they come with their own set of challenges:

- RF interference

- Limited range

- Poor signal-to-noise ratios

- And yes, they’ve even been tossed in the trash by accident!

So, for now, wired probes remain the standard.

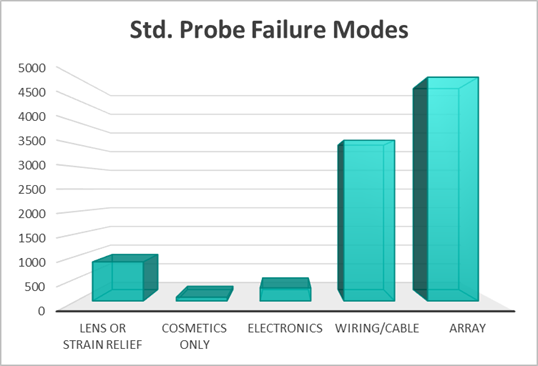

📊 What the Data Shows

We analyzed the past 2-years of standard probe repairs (omitting TEE and mechanical 3D probes). Of about 10,000 standard probe repairs:

- >50%: Acoustic array damage/failures

- ~37%: Wiring/cable failures

- 13%: Lens, strain relief, cosmetics, electronics

That means over a third of all probe failures could be traced back to the cable.

📈 Design Complexity Is Growing

Legacy probes may have had fewer than 100 micro-coaxial wires. Yes, ONLY less than 100. Typically, there was 1 wire per acoustic element.

More complex probe models, such as the Philips VL13-5, L12-5 50mm, and L18-5 increase the element counts in the acoustic array to 192, 256, and 288 respectively, yet still use a wiring harness containing about 170 wires. In these models, both the scanner and the probe electronics use multiplexers. The harness carries, not only the T/R signals, but also power and signals to control the Mux’s.

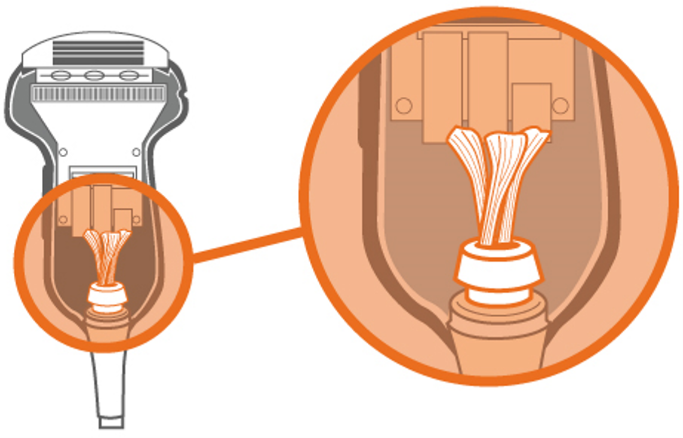

Newer live-3D volumetric probe models, such as the Philips X5-1c and GE 4Vc-D have over 3000 acoustic array elements, yet still only use a harness with less than 200 wires.

🔍 How Failures Show Up in the Field

Barring physical damage, when the cable is cut, pinched, rolled-over, or pulled, wiring failures occur as a normal part of almost every probe’s lifecycle. Wiring failures usually lead to service calls being placed for non-descript problems or general terms, such as noise artifacts. Depending upon the level of detail provided by the customer, wiring failures may be challenging to reproduce in the field without a consistent test process. Our transducer assessment guide provides step-by-step instructions on a consistent testing process. More information about the guide is below.

- Color Doppler: Vertical streaks or flashing lines of varying color

- CW Doppler: Crackling/static and sharp, white spikes in the spectral trace

- 2D Mode: Intermittent or constant “black” lines of image dropout

- Advanced Probes: Double/partial images or error codes

⚠️ Typical Fixes (and Their Risks)

- Cut-back & re-terminate: Shortens cable over time (and end-users notice)

- Used cable harvesting: You don’t know the age of the replacement cable (uncertain wear and tear; a gamble on longevity)

- Generic replacements: May compromise safety & performance and OEM design integrity

✅ Innovatus Imaging’s Solution

As an FDA-registered manufacturer, we:

- Fabricate 100+ unique cable assemblies

- Use wires as fine as 52-gauge (coaxial wires thinner than a human hair)

- Validate every solution against bench-marked specifications

- Deliver sustainable repairs that extend device lifecycle and reduce overall cost of ownership

We don’t just fix cables—we engineer solutions that restore performance and reliability.

📩 Want to Learn more?

We’ve developed a Transducer Assessment Guide to help you consistently test and evaluate probe performance.

👉 Email us at training@innovatusimaging.com