Over the past few years, several OEMs have released new MRI coil models that have strayed from traditional design. Philips dStream™ and GE AIR™ coils utilize updated technologies and updated designs to provide greater SNR and enhanced image quality. Philips dStream™ and GE AIR™ coils perform the same functions, but do so using updated technologies and updated designs providing greater SNR (signal-to-noise ratio) and enhanced image quality to clinicians. Learn how Innovatus engineers have decoded Philips dStream coils and can provide Error-free GE Air coils.

Expertise and Experience

It’s been over 35 years since our legacy company began manufacturing MRI coils and offering MRI coil repair. It began as a result of supporting coils manufactured for our OEM partners. A few years later, a single hospital in Pittsburgh, PA inquired if we could repair an MRI coil manufactured by one of our non-OEM partners. It made excellent business sense, and the rest is history. We possessed the knowledge-base and expertise required to design, manufacture, and service MRI coils. We had the engineering talent in-house, possessed the manufacturing skillsets, the machining to fabricate replacement parts, and an ISO 13485 certified quality management system and the leadership in-place to assure success. Fast-forward to 2023. Believe it or not, there are still a few original employees on our team.

Difference in Strength (Tesla)

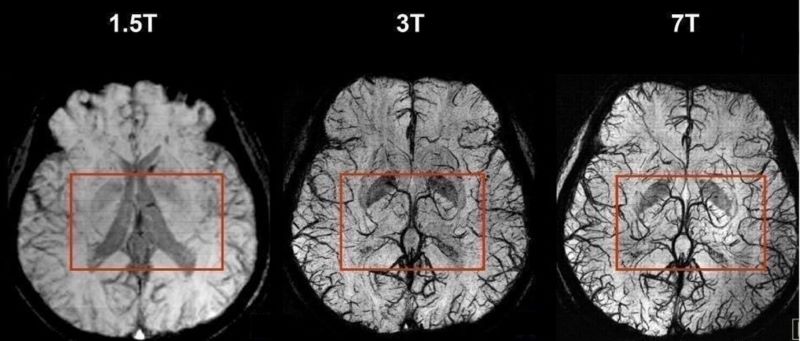

MRI strength is measured in Tesla (or T). The stronger the magnetic field, the greater the signal-to-noise ratio (SNR). Also, a stronger magnet enables the body to be imaged either 1) at greater resolution, or 2) at the same resolution, only faster. Back when we entered the service industry, MRI systems operated at 0.5T. Today’s healthcare systems utilize magnets with strengths of 1.5T – 3.0T. But it’s not going to stop there. The use of ultrahigh field systems is growing. In 2017, the first 7T system was cleared for clinical use in the U.S. and Europe. There are now dozens of 7T systems in-use worldwide. Currently, a 10.5T system is in-use at the University of Minnesota in their Center for Magnetic Resonance Research.

So, what’s the deal with developing these ultrahigh field systems? A 3T system has the potential to resolve tissue within the brain as small as 1mm. Cut that in-half (0.5mm) for a 7T system, and scanners at 10 – 11 T have been predicted to resolve down to 0.25mm. It will be quite some time before 7T systems are mainstream, as the ultra-high field systems cost about 10 – 14 million US dollars.

Above details courtesy of Nature, Nature 563, 24-26 (2018), doi: https://doi.org/10.1038/d41586-018-07182-7

Advancements in MRI Coil Design

With advancement in MRI scanner technology, so is it with MRI coil design. Greatly, greatly, simplified, an MRI coil is an antenna. The coil receives minute signals from the body as the protons in the body repolarize after being exposed to an RF signal while in the magnetic field.

One of the challenges with coil design is capturing the tiny signals with minimal signal loss (maximum SNR). One way that this is accomplished is to place the coil as close as possible to the region of interest. The closer a coil is placed to the region of interest, the better the SNR. It’s one of the reasons why there’s such a variety of coil designs.

GE AIR™ coils

One of the ways that GE has increased SNR is through the use of a new coil design on their latest SIGNA™ systems. With the exception of a solid-design head coil, GE’s latest coils look like blankets. Although flex coils have been around for years, nothing is as revolutionary as these. The entire coil is flexible and can be totally wrapped around the anatomy. You just can’t get any closer. All of the circuitry is mounted on a flexible, very lightweight, ribbon-like, conductive material. The entire flex circuit is embedded within a non-removeable protective cover. The challenge with anything flexible, is that the design must withstand continued flexing without compromising performance. What a challenge for the repair industry.

Philips dStream™ Coils

Although magnet strength has not increased much in the last 10 years, newer magnet designs offer increased receiver channels. Newer coil designs also offer increased receiver elements. The greater number of receivers, the greater the image resolution. The challenge with increasing the number of receivers is the need to increase the number of signal wires in an already very bulky system cable. The length of the system cable, the number of conductors, how well the cable is shielded, and how the cable is routed can influence the amount of external RF noise injected into the minute signals. As system cables are flexed over and over, they also become intermittent.

One way that Philips has addressed this challenge is through fiber optics. Philips’ latest system, Ingenia, utilizes a revolutionary coil design (dStream™). dStream™ coils digitize the minute analog signals, received by the coil, and transmit them to the system via a fiber optic system cable. Fiber optic signal transmission results in virtually no signal loss. It also allows for increased receiver element counts without the limitations of individual analog wires. What a concept! Another new challenge for the repair industry.

Challenge Accepted

Despite the radical technological and material advances within these new coil designs, Innovatus engineers have been able to develop comprehensive repair solutions. From a design perspective, many of the components within all coils are similar…resonance circuits, filters, pre-amps, etc. It’s how those components are configured, packaged, and the design as-a-whole that might pose the greatest challenge. We’re happy to share that Innovatus engineers have decoded Philips dStream coils and can provide Error-free GE Air coils.

Your GE Air™ coils can now be Air-free. Did you see what I did there, Error…Air? We are not limited by the flex circuitry within the Air™ coils, nor their new non-removeable packaging. As with all of our repair solutions, our engineers develop schematics, bills of materials, proprietary tools, and test procedures relative to each coil’s unique design. There is no one-size-fits-all repair. It’s a confident “Yes”, that we can repair your Air™ coil.

We’re happy to announce that, over a year ago, we dCoded Philips dStream™ coils. Our engineers have designed specialized test equipment that enables us to interrogate the fiber optics within these new coils. We’re able to assess the coil’s overall performance and address your failures. We’re also able to replace the fiber optic system cable. It’s a capability that few, if any other provider, can offer. We can repair a failed dStream™ coil for less than 5 – 10% of its replacement cost.

For more information on Innovatus’ comprehensive repair capabilities, or to arrange for the repair of one of these new coil designs, contact customercare@innovatusimaging.com or call 844-687-5100.