What Every Biomed Should Know About Ultrasound Probe Arrays

As an HTM professional, you’re constantly troubleshooting equipment. But what happens when an ultrasound probe isn’t producing clear images—despite looking perfectly fine on the outside? The answer often lies in one of the most fragile, misunderstood, and essential components: the acoustic array. After reading this, things should be crystal clear.

Introduction

We’re going to continue in a series focusing on some of the key components within an ultrasound probe. If you missed last month’s content, we focused on the acoustic lens. Many consider it just a rubber membrane that contacts the patient. The truth is that it the lens is much more complex than it appears, and it serves multiple purposes.

The most technically complex component within an ultrasound probe is the acoustic array. Ever wonder why ultrasound probes are referred to as transducers? A transducer is just a generic term for any device that converts energy from one form to another. Technically, a speaker is a transducer, as is a microphone. Following that thought stream, a lightbulb is a transducer, as is a thermistor, and as is a solar panel. Each of these examples converts energy from one form to another.

Look out, here comes the piezoelectric element. It has the ability to convert electrical energy into sound (technically mechanical) energy, and then reverse the process by converting sound (or mechanical) energy into electrical energy. Few, if any, other materials are able to translate energy in this manner. Think about it, a lightbulb cannot create electrical energy as a result of light being applied to it. To the layperson, the array might just seem to be some type of mystical component.

Technical Stuff

At the heart of an acoustic array are piezoelectric elements. Some still refer to these as “the crystals”. Why? In the early days of ultrasound, researchers discovered that applying pressure to crystals, such as quartz, tourmaline, and Rochelle salt generated electrical energy. The term stuck. The colloquial term “crystals” is quite a departure from the highly advanced acoustic materials used in today’s acoustic arrays. For much of the time that ultrasound technology has existed, ceramics, such as PZT (Lead Zirconate Titanate), have been used in acoustic arrays. Now, single crystal and CMUT technology are in mainstream use. We won’t dive into the technical differences or advantages/disadvantages of each. Keep in mind that, as acoustic arrays have become more advanced, they have also become more fragile.

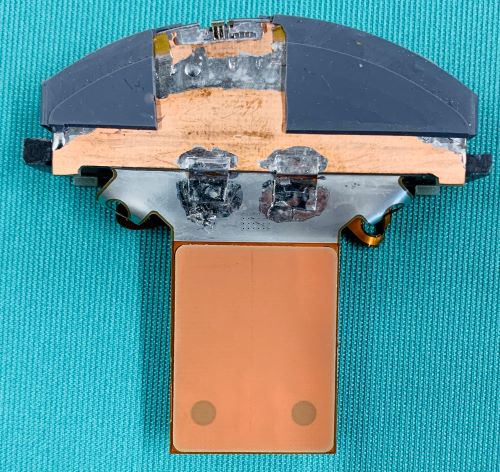

The acoustic array is much more than just a collection of piezoelectric elements. In design and manufacturing, the array is referred to as the acoustic stack. Today’s acoustic arrays resemble a sandwich that consists of multiple layers. At the core of the array are the piezoelectric elements which are commonly referred to as the “crystals”. Despite the size and weight of the entire array, the elements themselves, are extremely small. The height or thickness of a single element may be less than 0.4mm. Their thickness is typically compared to that of less than a hair.

Beneath the Surface

Beneath the array is a backing material to which the elements are bonded. The backing material serves two purposes, 1) To dampen the high frequency vibrations of the elements and provide a crisp clean signal, and 2) To direct the acoustic energy created in the appropriate direction…out of the probe, and into the patient.

On top of the elements are acoustic impedance matching layers. Matching layers are designed to maximize energy transfer from the array into the patient. The scan or acoustic coupling gel, applied between the probe and the patient is another type of a matching layer. Without scan gel, it’s almost impossible to acquire an image. The latest matrix array probes from Philips utilize 10 matching layers between the acoustic elements and the patient.

Common Failures

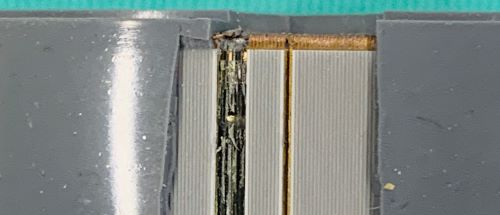

We can say, with confidence, that a strong majority of probes sent-in for repair have presented with performance problems due to traumatic array damage. Yet, there is no, or very little, evidence of an impact to the probe itself. Knowing that the ceramic-like acoustic elements are extremely thin and fragile, and knowing that the scan head weighs about a pound…when a probe falls to the floor or is accidentally dropped, the impact shatters a portion of the elements. The damaged elements may no longer resonate at the designed frequency or may not function at all.

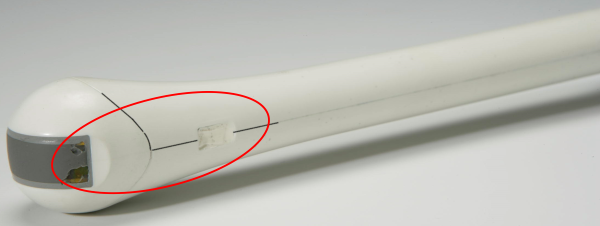

Another root cause of array damage is gross fluid invasion, related to TEE probes and other probe types that are high-level disinfected. If there’s a break in physical integrity (missing seal, hole in the lens, or open seam) disinfectant can enter the probe, short-circuit the scanhead electronics, and/or damage the array.

Common Symptoms

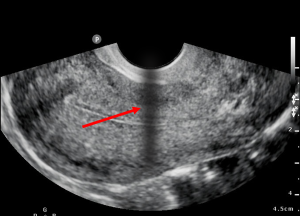

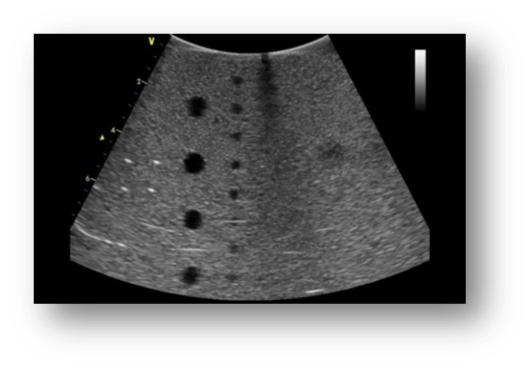

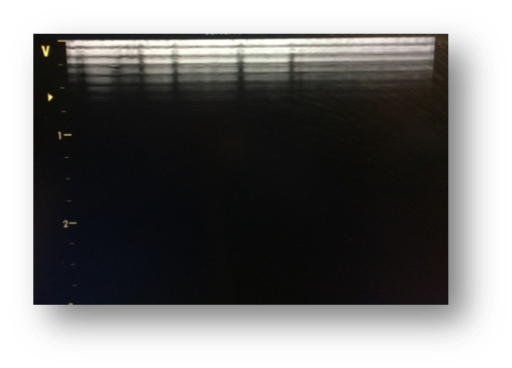

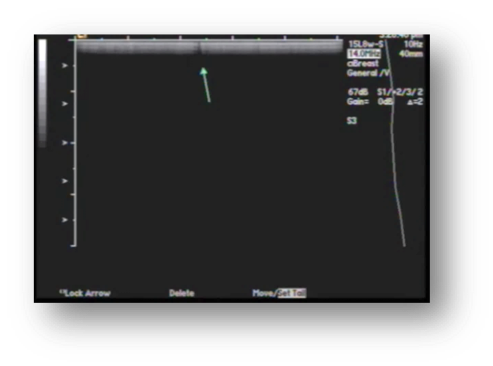

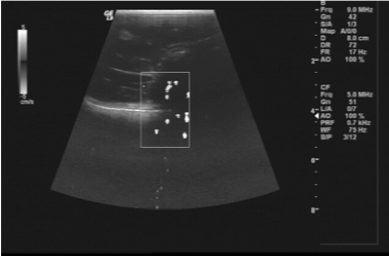

Typically, traumatic damage presents as a dark vertical line or vertical area of no information, called image dropout. In fact, ANYTHING that causes an acoustic element not to function can result in image dropout. Damage via fluid invasion (or internal contamination) usually presents as intermittent vertical white lines, streaking through the image. With more advanced probe designs, such as the Philips X5-1c, X8-2t, or GE 6VT-D, error codes may be displayed on the scanner console.

| Symptom | Likely Cause |

| Dark, vertical line (image dropout) | Cracked or damaged acoustic elements |

| White streaks or flashing lines | Fluid invasion, internal contamination |

| Scanner error codes | Electronic failures, short circuits, fluid invasion |

Don’t Replace — Repair

Innovatus Imaging is one of the only ultrasound probe repair companies in the U.S. with an FDA-registered facility that manufactures ultrasound probes and ultrasound-related devices for several prominent OEMs.

- We’ve repaired over 195,000 ultrasound probes spanning over 350 different models.

- Since the early 2000’s, we’ve been able to surgically repair or fully replace the acoustic array on over 160 of the most popular probe models.

- By being able to repair or replace the array, fully replace the wiring harness, and perform complex electrical repairs, we’re able to restore your probe’s performance…not just get it working again.

- Don’t just get your probe repaired—Restore its performance and lifecycle for a fraction of the cost of replacement.

What This Means for You and Your Clinicians

You play a pivotal role in:

– Detecting early warning signs

– Preventing catastrophic probe failures

– Avoiding unnecessary replacements, and

– Saving time and support costs for your customers

Final Takeaway

Next time you see a weird line on a scan or hear about a ‘dropped probe,’ think deeper. Think acoustic array. Because when it comes to ultrasound performance—It’s crystal clear: You’re the key to keeping it sharp.

Want to learn how to spot array damage confidently?

Get your FREE guide on how to perform ultrasound probe assessments.